Library: Resources & Media

Press Releases

ChemQuest Growth Trajectory Continues with Three New Directors

The ChemQuest Group is pleased to announce that three new directors have joined the firm to support ongoing growth: Geoffrey Webster, Ph.D.; Philip Williams; and Paul Bryant. Webster is an accomplished R&D leader who has driven technological innovation, product development, and commercialization initiatives. Located in West Yorkshire, UK, Williams has honed deep expertise in general management and operational excellence. Bryant has been actively involved in the coatings industry for nearly 60 years, working in sales and leadership roles with leading global companies.

ChemQuest Expands Business Development Team with New VP

The ChemQuest Group is pleased to announce that Ramki Subramanian, Ph.D., has joined its business development team as a vice president. Subramanian is a dynamic global leader who has spent 30 years developing expertise in technology development/commercialization and business development in the specialty chemicals, advanced materials, and energy sectors. He has considerable experience in championing “concept to commercialization” for new technologies and building new businesses by developing novel technologies, particularly in emerging markets.

Two New Directors Add Expertise to ChemQuest Team

The ChemQuest Group is pleased to announce the appointment of two new directors: John Giudici and William (Bill) Worms. An operations transformation leader, John has built considerable expertise in strategic planning and execution, manufacturing operations, performance and process improvements, product and quality management, and productivity optimization. Bill is a seasoned business executive with expertise leading public and private companies, associations, and employee stock ownership plan (ESOP) organizations.

Market Reports

Articles

Geopolitics and the Global Supply Chain: What’s Next?

As global trade fragments and regionalization accelerates, organizations will need to adopt differentiated structures and technology stacks—a one-size-fits-all approach will no longer suffice. More than anything else, we need to learn from the past, including from the recent, post-COVID past. Developing resilient and transparent supply chains is at the top of the list, when it comes to being prepared for geopolitical shifts that might affect global supply chains. This is closely followed by building a geopolitical view from the perspective of your own company.

Mastering Key Performance Indicators for Long-Term Success

Your company has undoubtedly developed key performance indicators (KPIs) for your operation. Depending on your specific products, facilities, personnel, etc., these KPIs likely focus on areas such as production volume, on-time delivery, production costs, and environmental health and safety (EH&S), among others. KPIs are important gauges of your company’s productivity and efficiency, but simply having KPIs does not guarantee success.

Mitigating Personnel Challenges through Strategic Partnerships

Personnel roles within specialty chemicals and advanced materials require specialized know-how and skills, making it incredibly difficult to find knowledgeable and experienced people to fill key positions. Unfortunately, not having fully staffed and skilled teams in place jeopardizes your company’s ability to succeed over the long term. How many potentially impactful initiatives have been abandoned due to a lack of internal resources? Too many, without a doubt.

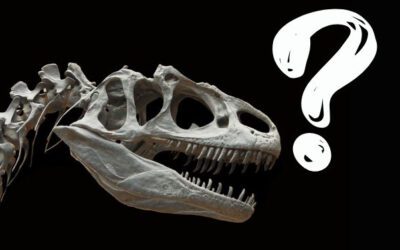

Salt Spray Testing: Dinosaur or Foundational Benchmark?

First published in 1939, one of the oldest specifications in the Committee D01 arsenal is ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus. It is still in active use today in a variety of markets to evaluate the comparative durability and performance of substrates in corrosive environments. This is despite some experts suggesting that the test is outdated and convenient rather than scientifically rigorous.

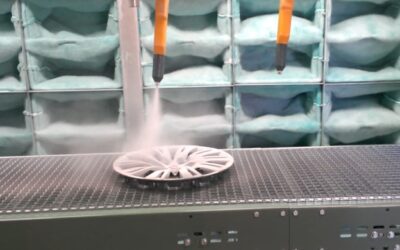

Powder Coating Nonconductive Substrates

Powder coating is traditionally applied electrostatically to a conductive (typically metal) substrate. The charged particles are attracted to the grounded object and uniformly deposited on the surface. However, as low-temperature-cure powder coatings become more available, the possibility of using them for coating a wide variety of heat-sensitive and nonconductive substrates is more of a reality than ever before.

Navigating the Maze, Part 4: The Final Filter – Using Quantitative Scoring to Prioritize Market Opportunities

You’ve assembled your interdisciplinary team, assessed market attractiveness and commercial feasibility, and validated technical and manufacturing readiness. Now comes the final step: prioritizing opportunities. When your list of promising projects exceeds your capacity to pursue them all, a structured scoring system ensures objective, data-driven decision making.