ChemQuest Technology Institute

Accelerate your R&D and Innovation Pipeline

ChemQuest Technology Institute is an unbiased knowledge resource for synthesis, formulation guidance, technology acceleration, raw material validation, and performance testing. Our team of advanced technical personnel are trusted experts within formulated materials industries, serving manufacturers, suppliers, and end users of coatings, adhesives, sealants, plastics, composites, and other formulated materials industries.

How can ChemQuest help you?

UNDERSTAND

your markets

& technologies

DEMONSTRATE

commercial

viability

DISCOVER

unexpected

features

ACCELERATE

commercial

adoption

SOLVE

problems and

determine root

cause

EDUCATE

internal

teams

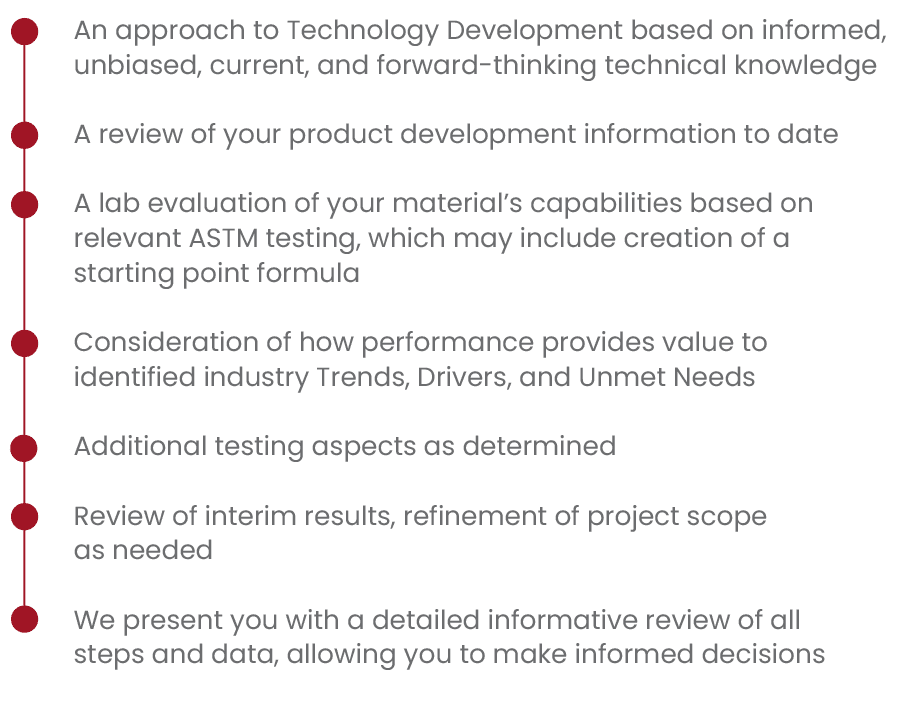

Our Technology Development Process

Our Clients:

- Raw Materials Suppliers

- Formulators

- Manufacturers

- End Users

- OEMs

- Distributors

- Start-ups

Our Services

- Material Analysis and Evaluation

- Formulation Design and Optimization

- Troubleshooting

- Application Refinement

- Expedited Testing Protocols

- Product Benchmarking and more

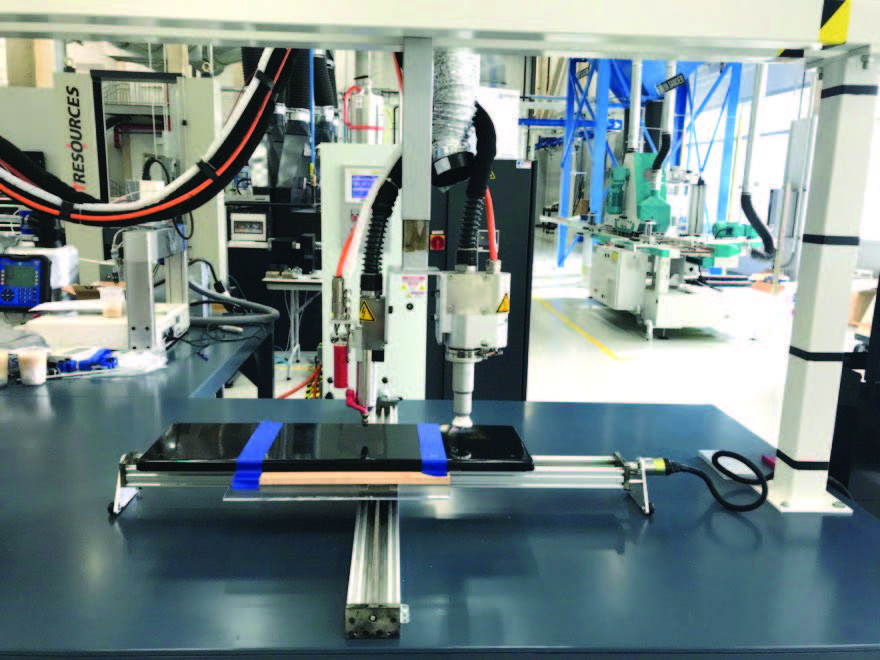

Advanced R&D Center

Our 16,000-sq-ft R&D and applications center houses both controlled lab environments and simulated manufacturing lines, where our deep bench of experts design, formulate, and validate products for the coatings, adhesives, sealants, polymers, plastics, composites, and other formulated materials industries.

Computerized Flat Line

- Material feed conveyor system with panel cleaner and pretreat

- Reciprocating dual spray valves, pressurized spray cabin

- Applies solvent and waterborne coatings

- Laminair, Convection I/R, and UV-cure options

Customized Hang Line

- Multiple curing options

- Programmable start/stop line

- Wet spray booth

- Robotics

Customized Surface Treatments with Atmospheric & Low-Pressure Plasma

- Key enabler technology for microfine cleaning, surface activation, and plasma coating

- For plastics, metals, glass, cardboard, textiles, and composites

- Makes processes more effective and sustainable

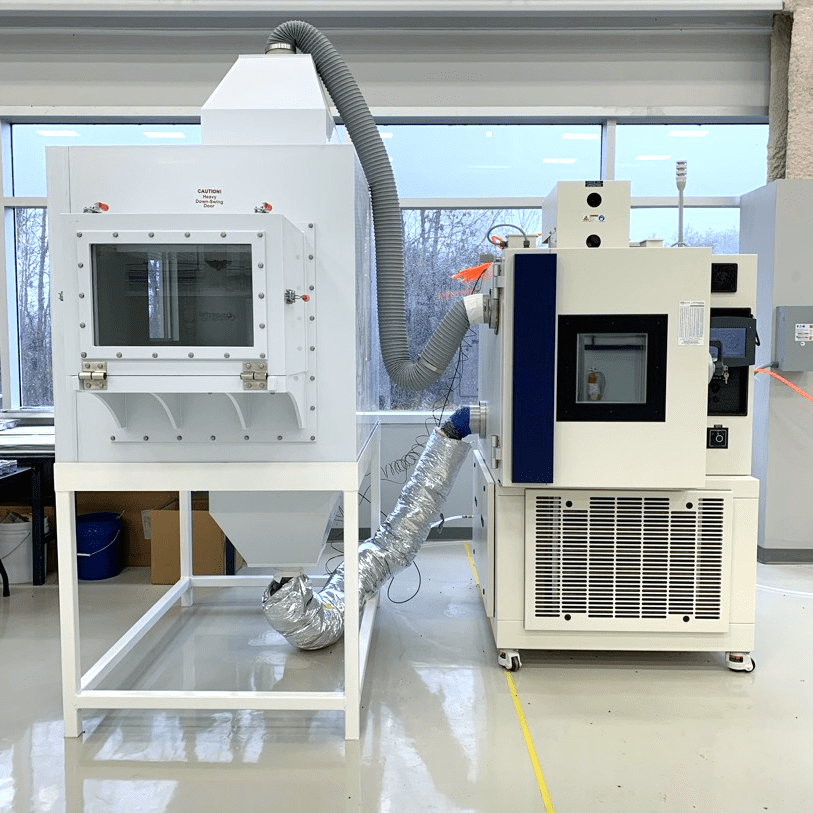

ClimateQuest™ Atmospheric Application Chamber

- Controlled temperature and humidity to mimic precise application conditions in various climates

- Brush, roll, and spray applications of solvent-based, water-based, and 100% solids materials

- Conventional, HVLP, airless, and air-assisted airless equipment

Polymer Processing Lab

- Thermoplastic formulation and evaluation