Table of Contents

Anyone who has been involved in developing raw materials for the coatings industry will tell you it is not a trivial undertaking. Over the years, we have seen many strategic thinkers who have been successful in other industries struggle when it comes to innovation in formulated products such as coatings.

Developing raw materials for this highly diverse and complex industry is difficult for multiple reasons, a few of which will be discussed in this article. Rather than relying on a general innovation process, it is highly recommended that raw material suppliers either acquire personnel with relevant coating experience or partner with an experienced third party to support their product development efforts in the coatings industry.

We recently worked on a project with a raw material supplier (let’s call them Supplier A) that has a commercial line of products used extensively in liquid coatings. This client wanted to determine if their products could be used to improve corrosion resistance in powder coating applications.

After discussing the potential project with the client, it became clear that their main goal was to determine if they could expand their addressable market into powder coatings applications; improved corrosion resistance was simply their hypothesis based on how the material worked in solventborne coatings. With this understanding, our consulting team developed a project that would not only answer their question about corrosion resistance but also ultimately inform them about additional benefits their materials could offer this new-to-them market.

Understanding the Innovation Process

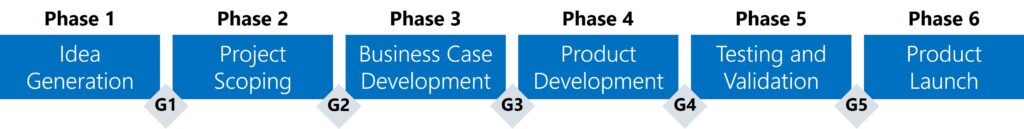

Most mid-sized companies and large corporations have an innovation process they follow when developing new products. These processes typically consist of five or six phases, with gates between each phase that serve as decision points to determine if the project should move forward into the next phase. A common high-level process is shown in Figure 1.

(Source: The ChemQuest Group, Inc.)

The process shown is intentionally general so it can be used across many industries. Most savvy companies that depend strongly on innovation, including coating raw material suppliers, have overlaid this general process with industry-relevant tactics that are used to guide the product development team through the innovation process.

In Supplier A’s case, their team was likely using an abbreviated version of this process, as they already had a product that was successful in one market segment and were looking to find utilization in an adjacent segment. This type of project is commonly referred to as a “product translation project” and does not require a product development phase. However, to be successful, the company needs to develop and prove out a value proposition for their product that is strong enough to displace currently used materials in the adjacent segment.

Supplier A had developed a hypothesized value proposition but did not have the capabilities required to validate (or reject) their hypothesis. In addition, even if they were able to develop the required corrosion-resistance data, they likely would have missed a hidden gem as they did not have strong knowledge of the unmet needs and materials currently used in powder coating applications. They made the correct decision early in the process to partner with a third party experienced in powder coatings to support their efforts and were rewarded in the end (more to come on that in a bit).

The challenge Supplier A faced is not uncommon in the coatings industry, as raw material suppliers find themselves in a continuous innovation cycle to prevent their products from becoming commoditized, or even obsolete. The coatings industry’s complexity and diversity make it almost impossible for one company to have deep technical and market knowledge in each segment.

In addition, innovating as a raw material supplier is a daunting task. Suppliers collect many bits of information as they go through the product development process but must piece them together to get the full picture. The reasons for this are mostly driven by where the supplier is in the value chain. While there are many variations of the value chain, depending on the specific coating application, one that is commonly seen in powder coatings is shown in Figure 2.

(Source: The ChemQuest Group, Inc.)

Being a few steps removed from the end user makes it somewhat difficult to get a true voice of customer with respect to unmet or underserved needs. Raw material suppliers are most often not well-connected with end users, and simply getting an end user to agree to a discussion can be a challenge. Of course, this can be overcome with enough effort or the use of a third party, but that is not the end of the story.

Since the new product will not be sold directly to end users, cooperation with coating manufacturers to develop coatings based on the new raw material is critical. However, end user and coating manufacturer incentives to improve coatings are often not aligned, which means new raw materials developed based solely on end-user input may never be implemented by the coating manufacturer. To further complicate matters, coating manufacturers are not typically transparent about their coating formulations or the segments they are targeting with new raw materials, because their formulations are a significant part of their competitive advantage.

Let’s consider a second example. “Supplier B” was developing a product for the broader coatings industry and wanted to determine if their product could be used to improve abrasion resistance in powder coating applications. They had developed enough data to garner interest from coating manufacturers, but the feedback from those evaluations was not positive. Of course, the coating manufacturers did not share the details of their evaluations; they just communicated that they didn’t see enough benefit to move forward.

After analyzing the client’s formulations and data, the reason became evident. Indeed, Supplier B’s product had shown an improvement in abrasion resistance, but only in comparison to a control formulation that did not take into consideration other formulation techniques known for improving abrasion resistance. This would have been obvious to someone experienced in coatings, but it is a common pitfall for those who are not well-versed in coatings or other “formulated products.”

You Don’t Know What You Don’t Know

Raw material suppliers with extensive experience in the coatings industry can effectively navigate this environment, as they have gathered market intelligence over many years and understand the landscape. They are aware of the unmet or underserved needs in their segments and can design well-thought-out experiments to facilitate product development.

On the other hand, raw material suppliers that aspire to enter new segments within the coatings industry may find themselves going “back to the drawing board” as it becomes clear the products they develop do not provide a strong value proposition to their customers. These companies should consider shortening their product development cycle by acquiring personnel with relevant coatings experience or partnering with an experienced third party to support their product development efforts.

In working on the project for Supplier A, the consulting team uncovered a benefit that was not related to corrosion resistance but offered a significantly stronger value proposition to the powder coating industry. (The specific benefit will not be described here for confidentiality reasons, but the material has the potential to displace products that are currently facing regulatory scrutiny across the industry.)

As a result, the client now has the potential to expand its addressable market into powder coatings with a much higher success rate than they were previously hoping for with their corrosion-resistance hypothesis. The company is now developing data for marketing collateral and a strategy to attack the market with a focus on this new value proposition.

To learn more, contact the author at ecasebolt@chemquest.com.

Read in PCI.