Library: Resources & Media

Press Releases

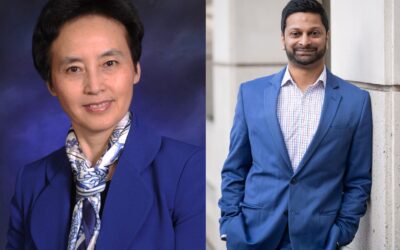

ChemQuest Deepens Bench of Experts with Two New Additions

The ChemQuest Group is pleased to welcome two new global leaders to its team. Sharon Feng, Ph.D., has been named a vice president, while Prem Patel has joined the firm as a director.

Dates Set for Fraunhofer IFAM European Adhesive Bonder (EABS) and European Adhesive Specialist (EAS) Courses in North America

The ChemQuest Group is pleased to announce that registration is open for two accredited adhesive bonding-focused courses in 2024. ChemQuest is Fraunhofer IFAM’s exclusive partner in North America for its European Adhesive Bonder (EAB) and European Adhesive Specialist (EAS) courses.

Wayne Daniell, Ph.D., Joins ChemQuest as Director EMEA

The ChemQuest Group has appointed Wayne Daniell, Ph.D., a director for the Europe, Middle East, and Africa (EMEA) region. During a career spanning more than 27 years, Daniell has founded and managed companies that developed nanomaterials and various coatings additives for use in markets such as consumer electronics, renewable energy, and white biotechnology.

Market Reports

Articles

Planning for the Future

Uncertainty continues to cause concern throughout the international business landscape, and the specialty chemicals and advanced materials sectors are no exception. When faced with shifting tariffs, escalating trade wars, and a volatile geopolitical climate, many companies choose a “wait and see” approach instead of taking proactive steps to ensure their long-term success. This risk-averse mindset is counterproductive, as inertia not only inhibits your company’s progress but hands your competitors the opportunity to pass you by.

ChemQuest Q&A: Rich Gibson

Rich Gibson joined ChemQuest as a director in 2021 after a more than 30-year career at Milliken & Co. In addition to assisting clients with projects in the Business Strategy & Transformation, Operational Excellence, and M&A Advisory pillars, he is also now part of our global business development team. I had the chance recently to catch up with Rich, learn more about his background, and hear his thoughts on trends that are influencing today’s business leaders.

Exploring the Data and Dynamics that Shape the Global Paint and Coatings Industry

The Global Market Analysis for the Paint & Coatings Industry (2024-2029) provides data, insights, and forecasts to deliver a thorough picture of the dynamics shaping the industry. While the complementary U.S. Market Analysis for the Paint & Coatings Industry (2023-2028) focuses on the domestic landscape, the Global Market Analysis provides an international scope. In addition, detailed regional chapters focus on North America, Europe, Asia Pacific, Latin America, and Middle East and Africa.

Matching Powder Coatings to End-Use Applications: A Practical Overview

Selecting the correct powder coating for a specific end-use application is critical but can be a mystery to applicators, product developers, and end users due to the variety of chemistries and industry terminology. Gaining a fundamental understanding of why certain powder coatings are used for specific applications can help you make more informed decisions.

Material Science Startup Technology: The Long and Winding Road Less Traveled

Much technology can be found at the university level, in various technology incubators, federal agencies, or small private laboratories, all with a unique perspective on providing solutions to common problems. However, with the explosion of artificial intelligence (AI) and other cloud-based technologies under development, material science labs face a much more difficult path forward when competing with more glamorous industries for resources.

Potential Solutions to the Low-Temperature-Cure Powder Coating Conundrum

Low-temperature-curable powder coatings are often touted as the next generation of coating technology due to their environmentally inoffensive list of ingredients, energy-saving cure requirements, and ability to coat a variety of substrates that cannot withstand typical powder coating curing processes. However, the processes by which powder coatings are produced impose limitations on how low we can ultimately drive the cure temperatures.