by Doug Corrigan, Ph.D., Vice President of ChemQuest Technology Institute, and Jim Swope, Chief Technology Officer, The ChemQuest Group

Manufacturers in nearly every industry and region around the world have dealt with numerous supply chain disruptions over the past several years. Identifying alternative sources for materials and products used in the manufacturing process is a necessary strategy for any company trying to limit the ramifications of these disruptions on its production capacity and end-product quality.

In most cases, finding a second source for a traditional fastener is fairly straightforward. Screws, nuts, and bolts are typically commodity products and readily available from myriad suppliers.

The process is much more complicated with adhesives, however, as adhesive performance varies quite broadly depending on the base chemistry and specific product formulation. Finding the optimal balance of properties for each application is therefore key when sourcing adhesives. However, this process can be challenging for companies that do not have personnel with a background in chemistry or a thorough understanding of adhesive formulations.

A manufacturer of architectural products ran into these challenges as it saw demand increase significantly due to the COVID-19 pandemic, and its longstanding overseas adhesives supplier could not keep up. Lacking the internal resources to identify a viable second adhesive source, the company turned to the ChemQuest Technology Institute (CQTI) for assistance.

Benchmarking Roadblocks

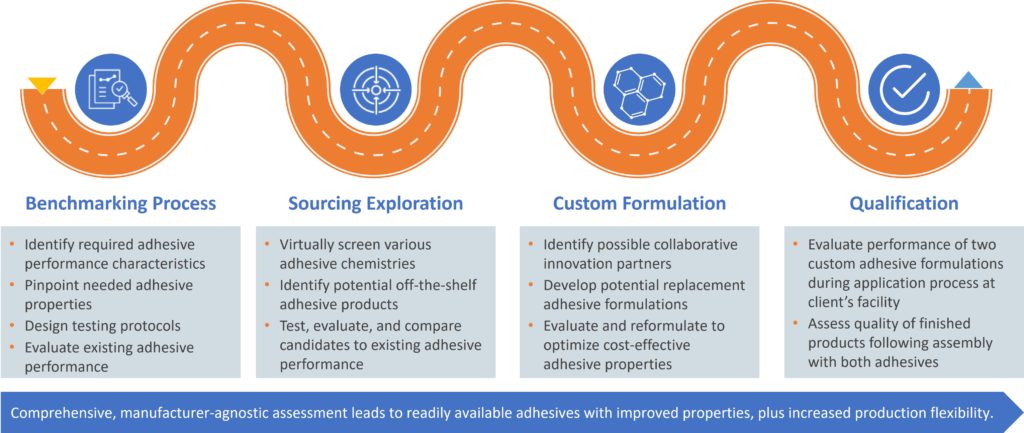

The first step in determining a suitable second source for adhesives is often to study the performance of the existing product. In this case, benchmark test data were not available, and specifications for applicable test methods and required performance properties were limited. The client had been successfully using the existing single-source adhesive for quite some time and had not felt the need to perform tests to validate the adhesive’s performance.

As a result, CQTI’s first task was to identify and design testing procedures that would enable us to benchmark the adhesive’s characteristics and performance. Our team determined the tests needed based on the adhesive’s performance requirements. For this application, it is important that the adhesive formulation is 100% solids (i.e., contains no solvents) and can be sprayed at a defined ratio.

Rheology is a highly significant property here as well, for numerous reasons. Rheology is essentially a measure of a material’s flow characteristics; thinner materials flow more readily than those that are thicker (think water vs. syrup). The rheology of this particular adhesive formulation needs to be thin enough to be sprayable but thick enough to remain on the substrate without dripping once applied.

An adhesive’s open time refers to the amount of time it takes for the adhesive to begin to form a solid as it cures. For example, cyanoacrylates (sometimes referred to as “superglues”) typically have short open times. Anyone who has inadvertently glued their fingers together knows that these products cure exceptionally quickly.

While a fast cure can be of benefit in numerous applications, longer open times are often actually necessary in multi-step manufacturing operations. If an adhesive cures too quickly, it might not be able to appropriately wet (or spread out on) the substrate as the part is assembled, which is necessary to create a full chemical bond. On the other hand, assembly operations often require parts to be manipulated or moved to another area of the facility after they are bonded. If the adhesive’s open time is too long (i.e., it has not sufficiently cured and begun to solidify), the parts will simply fall apart.

In truth, tailoring an adhesive’s open time can be a delicate balance. For this manufacturer’s application, the ideal open time is 45 min. This means that the assembled component can be handled 45 min. after the adhesive has been applied and the sections bonded together.

Since this manufacturer produces architectural components, the adhesive’s strength and durability are also key. The CQTI team discovered that traditional testing protocols were not sufficient to measure the adhesive’s performance in this application, so we designed and fabricated a new test device that more accurately reflected the mode of failure.

Second-Source Adhesives Exploration

Once the team completed testing to benchmark the existing adhesive product, we turned to the client’s original sourcing objective. The first step here is a virtual screening process, wherein numerous adhesives chemistries are considered with respect to the needs of the specific application. Depth of knowledge and experience are key in this phase, as an educated perspective reduces both time and cost requirements by narrowing down the potential chemistries without the need to perform broad testing.

After determining the ideal type of chemistry, the CQTI team investigated numerous suppliers of off-the-shelf adhesives to explore which could potentially meet the requirements of the client’s application. Some of the suppliers were suggested by the client, while others were considered good possibilities based on CQTI’s knowledge of the industry.

The adhesives that were determined to be a possible fit were put through the same testing procedures developed for the existing adhesive. Unfortunately, the results showed that none of them had the balance of properties needed for optimal performance in the application.

Custom Formulation Development

The need for a custom adhesive formulation became clear following the numerous unsuccessful tests of the existing commercial adhesives. During this phase of the project, CQTI reached out to known adhesives manufacturers, as well as a coatings producer with expertise in the desired chemistry, to gauge their interest in taking on this technology development project.

Throughout a comprehensive collaborative innovation process led by CQTI, two companies (the previously mentioned coatings producer and an adhesives manufacturer) developed multiple formulations in the quest to reach the best balance of finished properties while also addressing cost concerns. As a result, two adhesive formulations will soon go into field trials at the client’s facility. CQTI will evaluate both products’ properties during the application process, as well as the resulting quality of the client’s end products when assembled with both adhesives, to ensure suitability.

During the course of this project, CQTI also conducted additional evaluations on adhesive pump systems, with the goal of providing the client with added flexibility during the application process. The team was able to identify a customizable commercial system that will enable the operator to change from one adhesive to another without being limited by a specific mix ratio.

Unbiased Solutions

Though the client’s initial request for assistance in determining a second adhesive source was not as straightforward as it first appeared, the comprehensive, manufacturer-agnostic, third-party exploration of numerous options will provide widespread long-term benefits (see Figure 1). The CQTI team was able to pinpoint two nearby sources of this key manufacturing material, alleviating supply chain constraints and streamlining operations.

In addition, testing has shown that both new custom adhesive formulations outperform the existing adhesive product. Following field trials, we anticipate that the company’s products will benefit from increased reliability (i.e., fewer quality issues and field failures), as well as higher strength.

To learn more, contact the lead author at dcorrigan@chemquest.com or visit https://chemquest.com/cqti.

Read in ASSEMBLY