Table of Contents

Machined aluminum wheels, also known as diamond-cut wheels, are a staple of high-end automobiles due to their aesthetic appeal and performance, combining lightweight construction and durability with a striking appearance. The standout aesthetic feature of these wheels is the sharp contrast between the brightly machined aluminum surface and the colored background provided by the basecoat.

The coating systems applied to these wheels are critical to their durability, as they must protect the substrate against stone chips, scratches, automotive fluids, salt, and other corrosive materials. This article discusses the multi-layered coatings systems used for diamond-cut wheels, the function of each coating layer, and how liquid and powder coatings are used together to meet stringent performance and appearance requirements.

Understanding the Coating Process

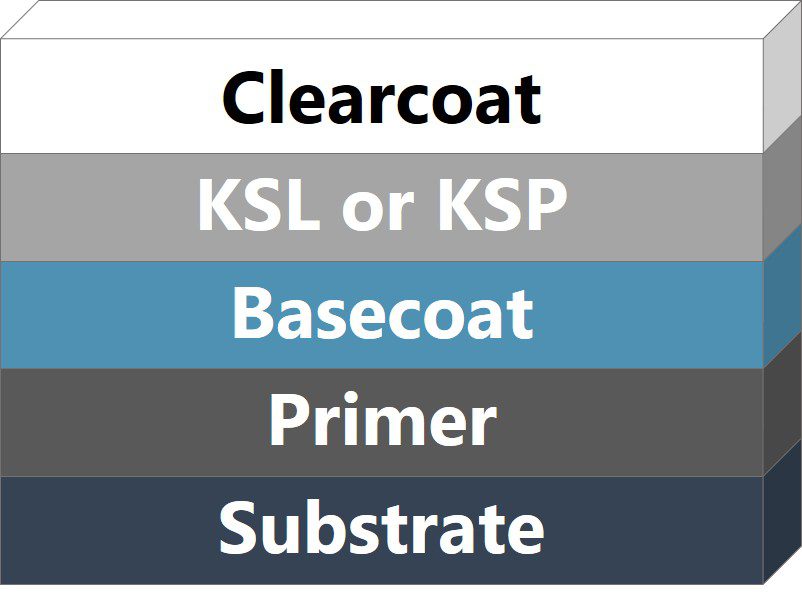

A typical diamond-cut wheel coating system involves four layers: a primer, basecoat, corrosion-protection layer (either KSL or KSP), and a clearcoat. These layers serve both decorative and protective purposes and can be visualized as shown in Figure 1.

(Source: The ChemQuest Group, Inc.)

While this image accurately depicts the coating layers, the process of coating a diamond-cut wheel is a bit more complex and can be conceptually visualized by the image in Figure 2. It’s important to note that the process involves multiple curing cycles, which are not shown here for the sake of simplification.

(Source: The ChemQuest Group, Inc.)

Surface Preparation

A deep dive into the surface preparation of aluminum wheels is beyond the scope of this discussion, but it is worth mentioning that it is a meticulous, multi-step process that includes mechanical blasting, cleaning, degassing, and the application of a chemical pretreatment to prepare the surface for the primer coating. While most steps of the surface preparation process likely seem familiar to those in the field of coatings, the degassing step may not.

Degassing involves heating the substrate to 200-250°C for a period of time to remove entrapped gasses from the casting process. If not properly degassed, these gasses can escape during curing and cause defects such as pinholes, craters, or adhesion loss.

Primer Layer

A primer serves as the foundation for subsequent coating layers by promoting adhesion and providing a smooth surface for the basecoat. In this manner, a primer contributes both to the performance and the final appearance of the coating system.

Primers are typically based on epoxy or epoxy/polyester hybrid powder coatings, as they provide the best adhesion and corrosion protection of the available powder coating chemistries. Compared to liquid coatings, powder coatings offer improved coverage and filling properties, especially over roughened substrates.

Basecoat Layer

The basecoat provides the wheel’s main color and visual effect. While both powder and liquid coatings may be used, liquid basecoats are preferred when metallics or mica pigments are used to create special effects. The basecoat is applied uniformly to ensure consistent color and coverage and must conform to stringent OEM color specifications.

Diamond Cutting

After the basecoat is applied and cured, the wheel undergoes diamond cutting, where parts of the surface are precision-machined to expose bare aluminum. This creates the signature contrast between the color of the basecoat and the bright aluminum substrate.

Machining also removes the protective coating layers from these areas, however, exposing them to potential filiform corrosion. This problem must be mitigated through the next layer in the system.

KSL, KSP, and Clearcoats

To protect the freshly machined surfaces, KSL (Korrosionsschutzlack) and KSP (Korrosionsschutzpulver) coatings are used in combination with the clearcoat. Both KSL and KSP translate to “corrosion protection coating,” with KSL being a liquid and KSP being a powder coating. While either can be used, each requires a specific clearcoat pairing, making a system-based approach essential.

KSP coatings are typically polyester powder coatings (TGIC or TGIC-free) that offer protection against filiform corrosion. However, to achieve high gloss, smoothness, and UV resistance, a liquid acrylic clearcoat is applied over the KSP. This is the more cost-effective solution of the two and provides acceptable performance and appearance.

The premium option uses a liquid KSL coating followed by a GMA acrylic powder clearcoat. This combination delivers exceptional smoothness, clarity, and depth-of-color and is often described as a Class A finish with crystal-clear transparency. The GMA acrylic powder coating not only enhances appearance but also boosts UV and chemical resistance, making this system the industry standard for high-end aluminum wheels.

Combining Forces

In diamond-cut wheel applications, it’s not a matter of powder vs. liquid coatings, but rather a systems-based approach that integrates both technologies for optimal performance and aesthetics. Powder primers provide robust coverage and corrosion resistance, liquid basecoats offer premium metallics and other special effect finishes, and the KSL or KSP layer in combination with the appropriate clearcoat completes the system. The result is a visually stunning coating that’s engineered to withstand real-world conditions when the rubber truly hits the road.

To learn more, reach out to the author at ecasebolt@chemquest.com.

Read in PCI.