Table of Contents

Color is the most critical and obvious coating attribute because it is essential to match both large industrial batches and small one-gallon cans of DIY paint, ensuring the final product is visually consistent for everyone. The question arises whether color perceived by the human eye or quantitative machine “true” color is better. An entire science of color measurement has developed over time to answer this question.

Measuring Color

Perceived color measurements, known as Specular Component Excluded (SCE), excludes the specular component (dominant type of reflection) to make the result more sensitive to scattered light caused by surface conditions such as texture and gloss. True color measurement, called Specular Component Included (SCI), captures all reflected light irrespective of the reflection—specular, diffuse, or scattered angle. SCE is the best way to verify true color during production, while appearance perception (i.e., metamerism, brightness) is best quantified with SCI.

Surface finish has a profound effect on color perception. The same true color on a high-gloss surface (≥70 GU) will appear to the eye more saturated and a semigloss surface (20-27 GU) will appear less saturated due to a decreasing spectral component of reflected light. A matte finish (<20 GU) will appear dull. As a result, most paint quality control and product parameters specify both gloss and color simultaneously.

Understanding ASTM Standards

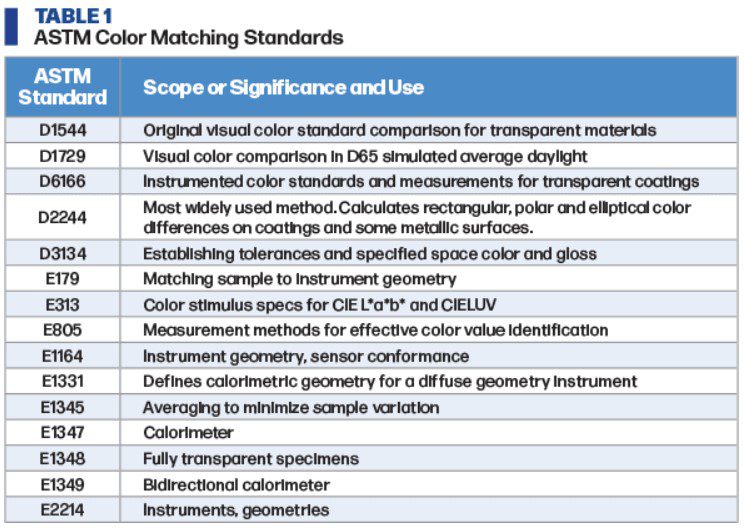

ASTM addresses color measurement parameters through a series of 16 standards. The parameters used within all but two of the ASTM standards are based on the CIE (Commission Internationale de l’Éclairage) system of tristimulus color measurement applied worldwide when measuring color. This system makes color measurements universally clear and globally meaningful. Table 1 lists ASTM standards available for color matching most paints and coatings.

Most color-measurement ASTM standards include definition of the following parameters: Color scale, CIE illuminant (defined white point, usually E D50 or D65 in color space diagrams), CIE Standard Observer (the 1964 10 Degree Supplementary Standard Observer represents most closely how the human eye perceives color), instrument geometry and mode, sample preparation, and sample presentation.

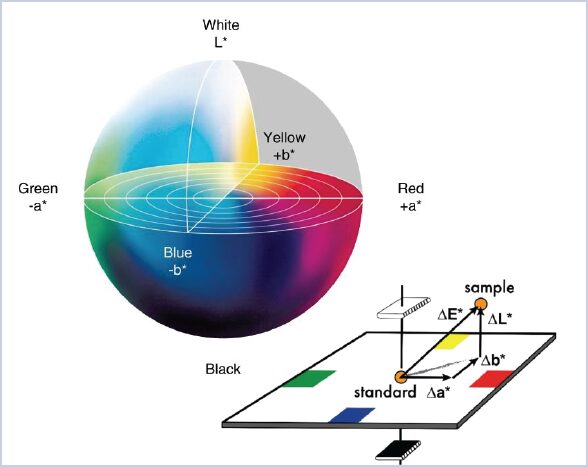

The L∗a∗b∗ technique mathematically defines color with a measurement instrument. The letters represent each of the three values the CIE L∗a∗b∗ color space uses to measure objective color and calculate color differences. L∗ represents lightness from black to white on a scale of zero to 100, while a∗ and b∗ represent chromaticity between the color produced and the standard, with no specific numeric limits. Color difference is the numerical comparison of a sample color to the standard. It indicates the differences in absolute color coordinates and is referred to as Delta (Δ). The overall differences, are defined as ΔE and calculated as follows:

This formula calculates the specific differences between two colors to assist in quality control as illustrated in the L∗a∗b∗ color sphere and calculation coordinates (see Figure 1).

Two types of instruments measure paint color in accordance with ASTM standards. Colorimeters see color like a human eye and can determine a location in color space by using values of tristimulus red, green, and blue and determining each color location with L∗a∗b∗ metrics. Spectrophotometers provide a more accurate measurement of color across the visible spectrum and filter light through narrow bands of color between 300 and 700 nanometers. These bands pass through instrument optics and receivers for recording as a unique reflectance band fingerprint for that sample. The latter is the best way to develop formulations, as it is more apt to eliminate most color-matching errors.[2]

The Gardner Color Scale measures the color of transparent liquids such as oils, varnishes lacquers, fatty acids, lecithin, sunflower, and linseed oil. It is a strictly visual one-dimensional, single-number analysis that is either manual (ASTM D1544) or instrumented (ASTM D6166). As presented in Table 1, established ASTM standards and methods universally identify, compare, and set color parameters, ensuring consistency and reliability, whether using precise machine measurements or the human eye.

For more information regarding ASTM standards, reach out to the author at cgosselin@chemquest.com.

Read in CoatingsTech.

References

1. Saju, Abhijut K. Understanding Solor Space and Delta E. Havells India, Ltd. LinkedIn. 2023. https://www.linkedin.com/posts/abhijeetksahu_linkedin-community-colorscience-deltae-activity-7088421572566249472-ruPT/ (accessed July 31, 2024).

2. X-Rite Pantone® Color Blog. Color Measurement Devices. X-Rite Color. June 19, 2022. https://www.xrite.com/blog/color-measurement-devices (accessed July 31, 2024).