Table of Contents

Since the 1930s, the most prevalent test for the evaluation of coating adhesion has been the manual tape-and-peel test. Pressure-sensitive adhesive tape (initially 3M™ 710 until it was discontinued in the mid-1930s) is uniformly pressed against a coating. Once the tape is peeled off, the amount of film removed from the substrate observed on the tape or the sample is rated against various photographic or rating standards. While ASTM standards provide a universal methodology, the analysis of test results (i.e., pass/fail, acceptability, relative performance) is a function of product specification, developmental baseline, quality standards, etc.

Test Methods and Procedures

Codified in 1974, ASTM D3359 Standard Test Method for Measuring Adhesion by Tape Test is the most well-known and widely used method for tape testing. Even today, this standard sells more individual copies than any of the hundreds of other standards in ASTM Committee D01. This convenient, relatively simple, and quick adhesion-test method has been a very good technique for comparative and quality testing.

ASTM D4541 Standard Test Method for Pull-Off Strength of Coating Using Portable Adhesion Testers is another well-known standard, but it requires the use of an apparatus known as a pull-off adhesion tester and is not as convenient. Further, the different models of testing apparatus can yield different results, which can cause confusion or inhibit direct comparisons between materials.

Other ASTM standards that utilize/reference tape testing include:

- D2794 Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact)

- D4145 Standard Test Method for Coating Flexibility of Prepainted Steel

- D4146 Standard Test Method for Formability of Zinc-Rich Primer/Chromate Complex Coatings on Steel

- D6491 Standard Practice for Evaluation of Aging Resistance of Prestressed Prepainted Metal in a Dry Heat Test

- D6665 Standard Practice for Evaluation of Aging Resistance of Pre-stressed Prepainted Metal in a Boiling Water Test

- D7093 Standard Test Method for Formability of Thin Film Organic Coatings on Steel Over a Biaxially Stretched Dome

- A1122/1122M Standard Test Method for Bend Testing of Metallic-Coated Steel Sheet to Evaluate Coating Adhesion

Prior to the tape application, the paint film to be tested is generally damaged in some fashion to create a “defect” starting point for delamination. Single longitudinal or vertical scribes, X-scribes made at 30-45° angles between legs or crosshatch patterns with preset blades are common. All cuts (scribes) should go through the paint film(s) to the base substrate, without gouging the substrate. Variations on the theme using mechanical damage include forming t-bends, Olsen domes, impact domes, or drawn 22% stretch domes, and taping those shapes before and/or after testing.

Other test modifications can be made as well. For example, to assess the effects of water on adhesion, a sample may be immersed in water or exposed to high humidity prior to tape testing; in fact, there are also ASTM standards governing exposure methodology.

Conversely, there are times when the adhesion integrity of a metallic-coated substrate (galvanized, galvanneal, aluminized, Zn/Al/Mg, etc.) is required. To accommodate this, ASTM A1122/1122M was developed. This standard utilizes the t-bend test (as in D4145), conducted on bare metallic-coated substrate prior to painting. For convenience, these standards are cross-referenced should the examination of both the substrate and paint film be desired.

Tape is subsequently applied to the damaged area and removed. Rating systems are used to evaluate the level of adhesion (or delamination). When testing initial adhesion between organic coating layers (e.g., intercoat adhesion between primer and topcoat), scribing can be but is not always necessary. In this case, simply applying and removing the tape and determining whether there is any removal of the top layer can be sufficient.

Tape Selection

Since the late 1930s, 3M™ Scotch Cellophane Film Tape 610 has been the specified/preferred tape for use in a wide array of adhesion testing. However, in February 2022, the 3M™ 610 tape was discontinued. This was problematic because so many comparative analyses had been performed involving paint and painted products that lasted from one-year to 30-year warranted material. It was extremely important that any substitute tapes provide data comparative to that of the past nine decades.

To that end, the National Coil Coating Association (NCCA) Technical Committee conducted a study to determine which tape(s) would best replicate 3M™ 610 data. NCCA testing determined that the tape properties were more important than specifying a particular branded product.

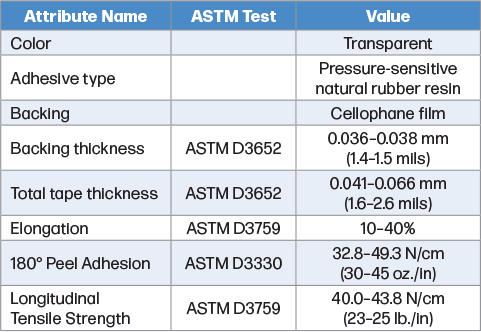

3M™ 681 tape was found to most closely reflect the desired properties and performance. Data from the study yielded the following performance characteristics for a clear, pressure-sensitive tape to be used for adhesion testing:

Evolving Standards

ASTM Committee D01 standards that require the use of tape for adhesion testing are currently under ballot review per ASTM protocol. Language that defines tape performance characteristics is being added to the relevant standards. Additionally, 3M™ 681 tape will be identified in non-mandatory footnotes as to the tape currently meeting performance standards, but the use of a specific product/brand will not be mandated per ASTM product advocacy rules.

To learn more, reach out to the author at cgosselin@chemquest.com.

Read in CoatingsTech.