Q: There is a competition among the powder suppliers. One after the other is bringing aggressive pricing to get our business, which is very attractive to purchasing. What basic criteria should be adopted to compare product when choosing one, in the simplest way to understand if one will be cost effective and meets quality expectations?

Your comments and guidance will be greatly appreciated.

A: This is a very pertinent question in economically changing times and with an industry that has been described as “mature.” Everyone is hungry for business. Consequently, powder coating suppliers are being aggressive in their quest for market share. Here is how I would approach this avalanche of prospective suppliers.

In choosing a vendor, I examine four crucial aspects of the supply relationship: quality, price, service, and supply.

Quality

Initial quality can be gauged through specification testing. If you do not have a specification for your product needs, establish one. This gives you a measuring stick to compare the quality of various suppliers. Be sure to perform qualification testing over production-real substrates and processing conditions. I would have your candidate suppliers submit test results (lab test panels, data, and a report) per your specification.

If convinced of the product’s preliminary quality, then take the qualification process a step further by running a production trial over relevant substrate(s) using your pretreatment, application, and curing systems. Then test these samples for pertinent specification performance including solvent resistance and corrosion testing. Test more than one product to confirm consistent performance throughout their product lines.

In addition, both a technical data sheet (TDS) and safety data sheet (SDS) should be provided for every product offered to you. The TDS will detail the performance expected of the product, including recommended curing conditions. The SDS will explain the presence of hazardous ingredients (if any), personal protective equipment, handling procedures, and disposal issues.

Ongoing quality should be monitored by requiring a certificate of analysis (CoA) for every shipment. I would ask for color, gloss, cleanliness, and particle size measurements to be included in every CoA. A CoA should represent every batch of powder manufactured. If more than one batch is included in a shipment, the appropriate number of CoAs should be provided.

Price

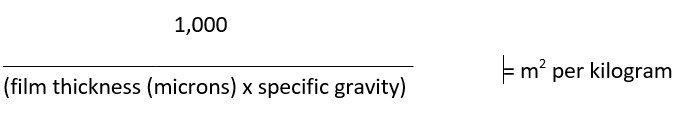

Look at value not only from a cost per kilogram (or pound) basis, but from an applied cost basis. This requires you to look at the specific gravity of the product and calculate theoretical coverage per kilogram. This can be calculated using this equation:

This value is the theoretical coverage of one kilogram of powder at a specified film thickness, assuming 100% transfer efficiency. You have to consider the transfer efficiency carefully. Powders from different suppliers will vary in application properties and therefore film build.

Service

Ask your prospective suppliers about how they intend to support your manufacturing goals. How often can you expect a visit from a technically capable individual? How big is their technical service staff, and how quickly can they respond when you have a problem?

Keep in mind that sometimes a smaller company can out-service a larger one because they may view your business as more important. And also realize that, ultimately, you are buying from people and not a company.

Do you trust your primary contact? Can you believe their explanations and commitments? Does their company support them? Will they include support efforts such as regular visits and line audits?

Supply

Finally, how will the supplier support your physical needs? Will they always keep an inventory of your products on hand? What’s their turnaround time on existing products? What’s their turnaround time on new products or small custom batches?

One of the best ways to assess a potential supplier is to pay them a visit. Take a look at their manufacturing and quality control processes. Also take time to meet their internal support people (inside sales, shipping, technical, etc.). Do they instill confidence that they will support you?

A successful relationship with a supplier requires more than just price per kilogram. You have to consider them part of your team to meet your customers’ demands. Will they embrace your needs as their own? In the end, it’s not always the vendor with the cheapest products that will bring the most value to your operation.