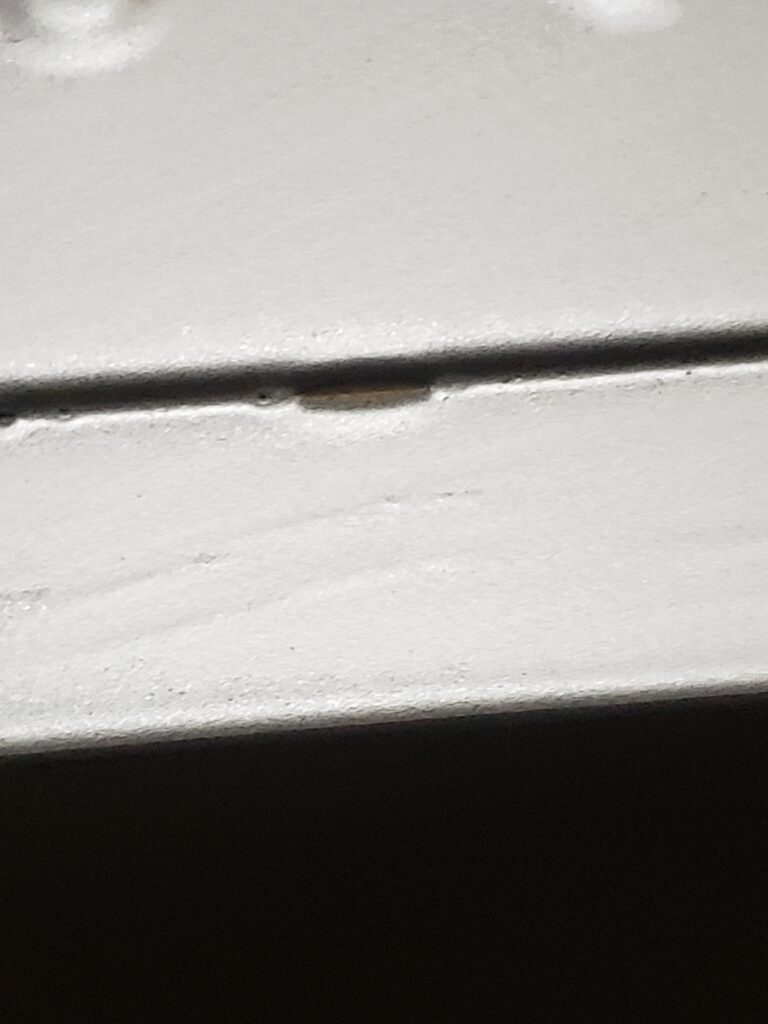

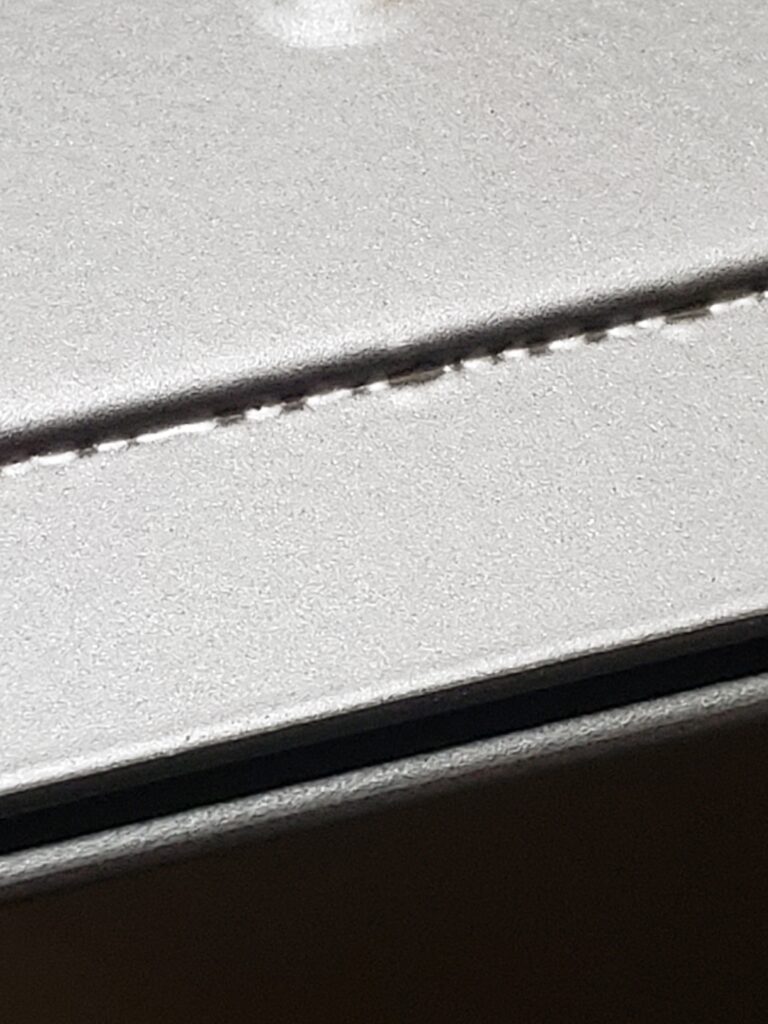

Q: I am dealing with a very perplexing issue on some parts, and I’m out of answers for my upper-management team. I have attached photos of the pinholes and voids we are seeing on our parts. Also in the photos are the thickness of the problem areas.

This is a TGIC-free metallic powder for a major appliance manufacturer. We reach the cure parameters as required by the manufacturer, so undercure has been ruled out. I also understand that TGIC-free powder can be very sensitive to film thickness and likes to crater and blister when it’s too thick or too thin.

We run a six-stage pretreatment system with an iron phosphate conversion coating. The parts pass the water break test going through the system but still come out with discoloring of the substrate in spots. We see no visible defects in the dry coating, like wet spots or oil spots on the substrate. It’s only after the cure oven that we see the defects.

The curious thing about it is the problem appears on the parts and disappears on the same parts a few racks later, then reappears a few racks after that. I’ve been doing this for 20 years and I have my suspicions, but they’ve fallen on deaf ears.

A: Wow, this is a messy situation. Those defects look rather ugly. The substrate appears to be a cast metal. Cast metal substrates can be porous, depending on the casting process. The defects shown in the pictures look like they are caused by volatile materials exiting the substrate during the curing process. This can be residual water from the metal pretreatment process, specifically the final rinse stage.

How good is your dry-off process after your pretreatment stages? And how good is the part orientation on your conveyor system? Can water collect in any areas of the parts and not get fully driven off before entering the powder spray booth? You should inspect the parts before they enter the application area to ensure that they are clean and, most importantly, dry before the powder is applied.

As for the TGIC-free polyester, the coating-related defects inherent to this chemistry are typically pinholes that are nearly microscopic and always associated with thick films. Consequently, I don’t think 50 or so microns would exhibit these kinds of defects.